Blygold Vietnam

Corrosion Protection

BLYGOLD is the first choice for corrosion protection on HVAC equipment

OUR SERVICES

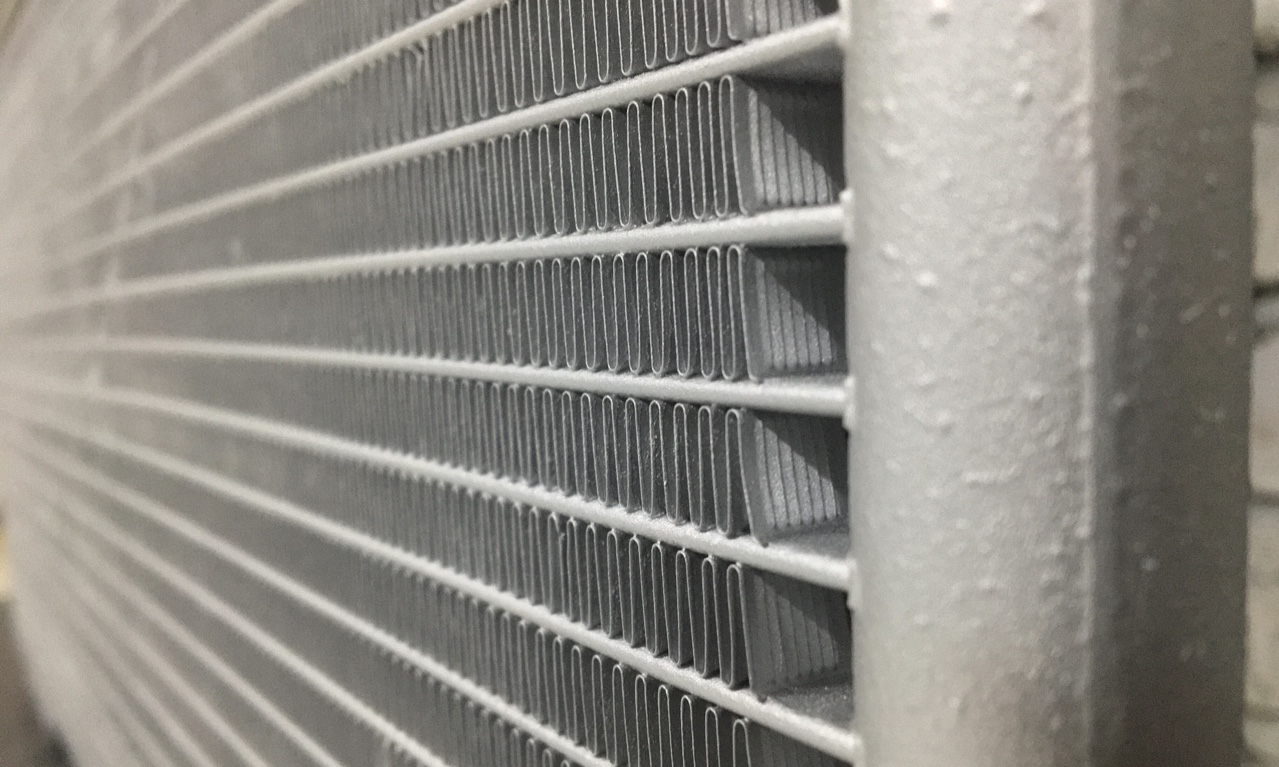

Round Tube Plate Fin Coil Coating

PoluAl XT/MB

Microchannel HX Coating

PoluAl MC

Finned Tube Coating

PoluAl High Temp

Cabinet & Casing Coating

Primer Refamac 3509 & Topcoat PoluAl

Foreword

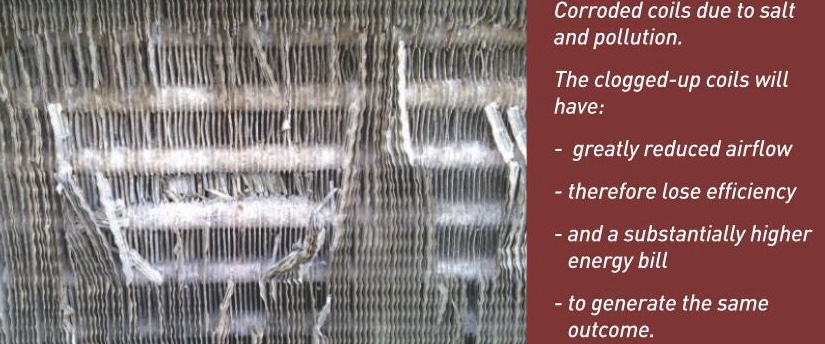

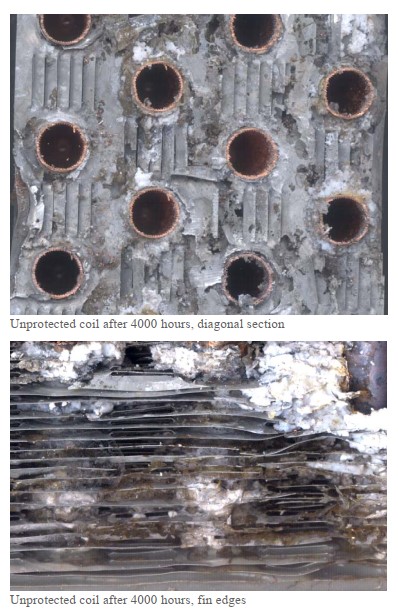

Combating the damaging effects of highly corrosive elements in heavy-duty environments is a key goal of every building manager and HVAC technician. Within the first year of HVAC installation, HVAC coils can become 50 percent corroded putting a large amount of pressure on technician and building managers to provide key quality controls and ensure HVAC units are properly maintained.

Winds and rain along seacoasts and industrial urban carry highly acidic particles into an HVAC system, and once inside the unit, these solutes and minerals can damage HVAC coils by eating away at the aluminum and copper metals because of the huge volume and contents of the polluted air coming through heat exchangers. Over time, the unit’s ability to transfer heat drops due to servere corrosion. This can drive up energy costs and reduce cooling capabilities.

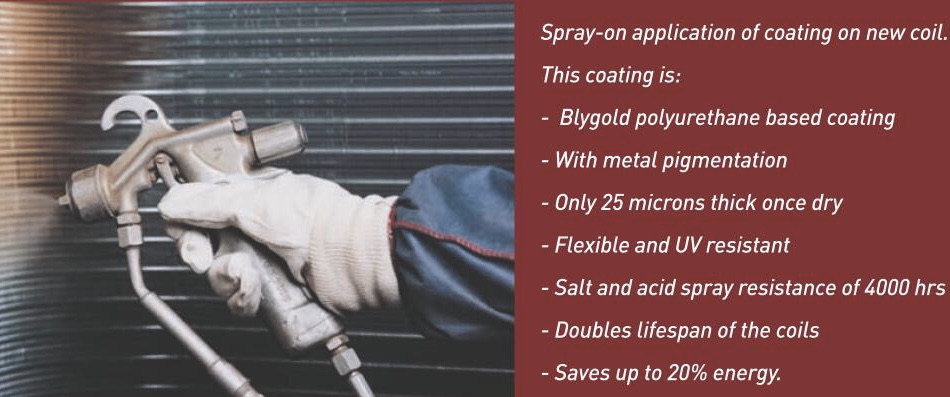

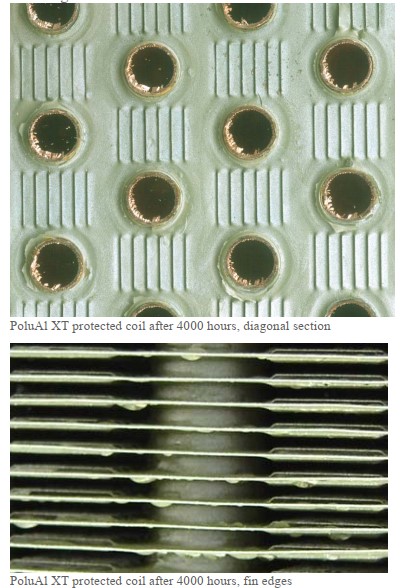

By applying protective coatings to HVAC systems, we can increase the life spans of HVAC systems and provide real-world energy savings. For applications that require a high level of protection againts coastal element, manufactures and distribitors typically turn to Blygold coating, which is an aluminum pigmented polyurethane. Since the coating contains heat-conductive pigmentation, a thin layer creates a high level of chemical resistance while maintaining heat-transfereability of the heat-exchanger coils.

Our Services

Blygold PoluAl XT With 4000 hours ASTM B117 Salt Spray Test

Our Core Values

Quality

![]() Over 40 years of experience

Over 40 years of experience

![]() Unique application techniques

Unique application techniques

![]() Unrivalled test results

Unrivalled test results

![]() All trained & qualified applicators

All trained & qualified applicators

![]() Global Quality Standard

Global Quality Standard

![]() ISO 9001 Certified

ISO 9001 Certified

Innovation

![]() Revolutionary R&D

Revolutionary R&D

![]() Inhouse laboratory

Inhouse laboratory

![]() Deep understanding of the Market

Deep understanding of the Market

![]() Global awareness of customer needs

Global awareness of customer needs

![]() Problem solving mentality

Problem solving mentality

Sustainability

![]() Lifetime extending

Lifetime extending

![]() Energy saving & Eco Friendly

Energy saving & Eco Friendly

![]() Life Cycle Cost reducing

Life Cycle Cost reducing

![]() Maintenance friendly

Maintenance friendly

![]() Corporate Social Responsibility

Corporate Social Responsibility

Years Established

Countries global network

Blygold Vietnam

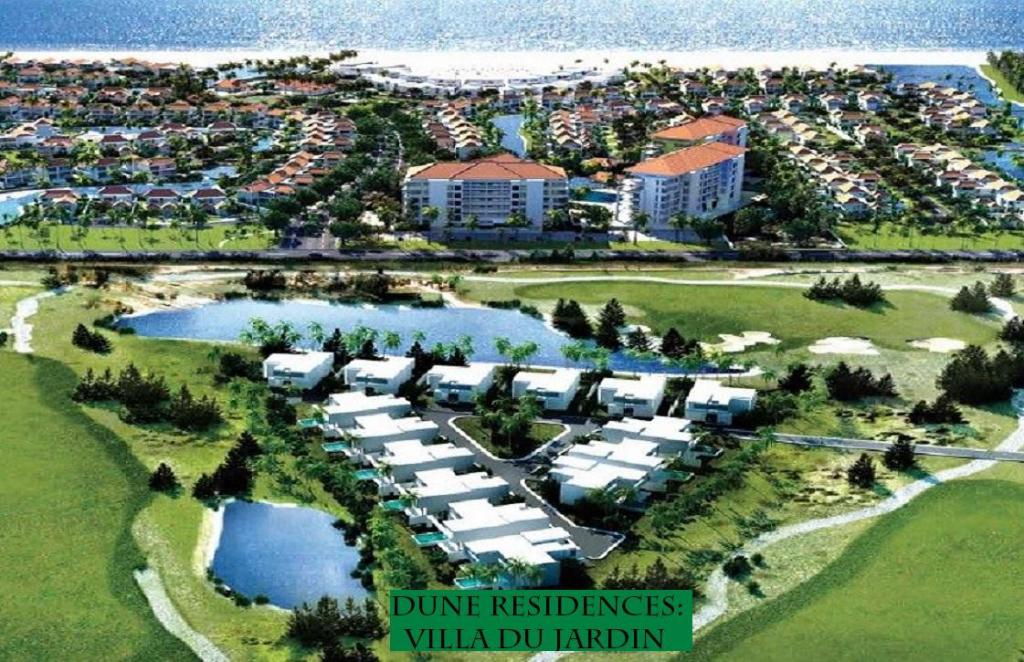

Blygold Vietnam was established in early 2018 based on the Agreement between Blygold International B.V. and ILS Corp. in Vietnam, which granted Blygold Vietnam the exclusive right as the Mastor-Franchisor within the teritory of the country. Following the Initial Training for Blygold Vietnam held in the Blygold International’s Headquater in Houten, The Netherlands on July 23-27 of 2018, Blygold Vietnam has been authorised as the certified and licenced Blygold applicator and in fully operational…

Call For a Quote:

(+84) 0918 540 913

A Selection Of Blygold Vietnam’s Activities

- Blygold Partner Meeting 2019 in Milan: Meet the Blygold Partners from 22 countries in a regular conference held by Blygold International every 3 years and visited Blygold Italy’s workshop on 2-3/10/2019 at STRAF hotel

Blygold Vietnam attended Blygold International Partner Meeting 2019 in Milan

Blygold Vietnam visited Blygold Italy’s Workshop in Milan

The Lastest Projects Of Blygold Vietnam

Lotte-Sea Logistics Long An - On-site Application

Lotte-Sea Logistics , Long Hau Industrial Area, Long An Province

Client: VSD Viet Nam Co., Ltd

Blygold PoluAl-XT coating for Air Handling Unit model AHN-453, equipment item HVU-01, icluding HX coils and attached casing

Lotte-Sea Logistics Long An

Lotte-Sea Logistics Warehouse, Long Hau Industrial Area, Long An Province

Client: Entanpi Technical and Trading Co., Ltd

Blygold primer Refamac 3509 and top coat PoluAl-XT for about 700 m2 surface of air ducts and its accessories

Frequently

Asked

Questions

Does a Blygold coating affect the thermal resistance of a heat exchanger?

Yes, no matter what others may tell you, every corrosion protection system has an effect on thermal resistance. This is due to the fact that no coating on the market today has the same heat conductive capacity as pure metals such as aluminum and copper. To what extent a coating will affect the heat transfer depends on the type of coating, heat exchanger geometry, air velocity ect. Blygold coatings are heat conductive and applied as a very thin layer. This results in minimal influence on thermal resistance and a minimal pressure drop. Tests of Blygold coatings have shown influences ranging from 0 to 12% depending on face air velocity and coil geometry. Installations with existing corrosion capacity. For normal situations we recommend using 3% as an average capacity loss.

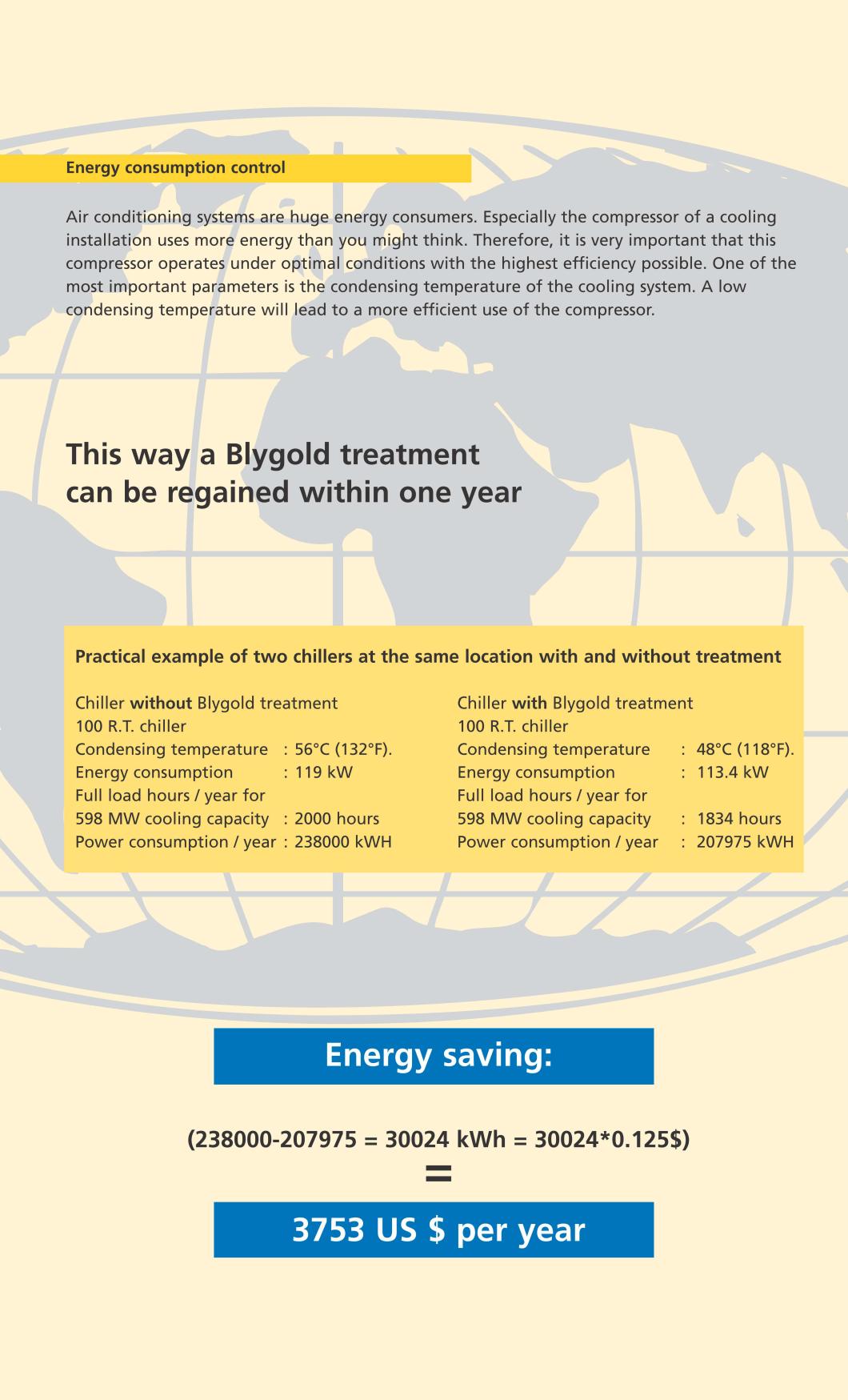

How does corrosion affect the capacity of my air-conditioning?

Corrosion will cause your air-conditioner to loose efficiency and capacity, which results in the air-conditioner consuming more energy and producing less cooling capacity. Your installation will therefore perform the worst when you need it the most. Heat exchangers are extremely vulnerable to corrosion due to the combination of different metals in the heat exchanger (copper and aluminum) and the continuous exposure to pollution and corrosive elements in the environment. The heat transfer between the liquid/gas medium in the tubes and the outside air passing over the fins is reduced due to the corrosion of the

aluminum. In addition, the pollution on the fins will reduce the airflow through the heat exchanger significantly. To release all the absorbed heat from the air-conditioned space the system raises the condensing temperature/pressure, this results in a higher temperature difference between the gas/liquid and the outside air. This high condensing temperature/pressure is why the compressor of your air conditioner consumes more energy and often fails in the summer period

What is the difference between pre-coat (epoxy, vinyl) and Blygold?

Blygold’s coating is aluminum-impregnated polyurethane, which is applied after the heat exchanger is assembled to allow for total coverage and complete penetration. Epoxy/vinyl coatings are inferior to polyurethane by their composition and the pre-coat process does not permit total coverage due to the cut edges being exposed after fabrication. Not only will pre-coat systems have a temporary effect against corrosion, they will also reduce the initial capacity by 15% due to the layer between copper and aluminum

Why is my air-conditioning unit corroding?

There may be any number of reasons why your air-conditioning unit is corroding. The heat exchanger in an air-conditioner is usually made from aluminum fins and copper tubes. With these two different metals, in combination with pollution and moisture, there is a huge potential for galvanic corrosion to take place. Aluminum will corrode rapidly around the copper tubes. Other corrosive agents and pollutants in the atmosphere, like sulfur, carbon dioxide and nitrogen, are able to directly react with aluminum and copper. Huge volumes of air are forced through the heat exchangers and this means they are are exposed to far more aggressive circumstances than other equipment

Energy Saving Efficiency Of Blygold Coating

A Selection Of Partnerships

Contact Us

76/8A Thanh Sơn, Thanh Binh ward, Hai Chau dist., Da Nang, Vietnam

![]() 8/10 Gò Dầu, Tân Sơn Nhi ward, Tân Phu dist., Ho Chi Minh city, Vietnam

8/10 Gò Dầu, Tân Sơn Nhi ward, Tân Phu dist., Ho Chi Minh city, Vietnam

![]() Trần Đức street, Hoa Khanh Nam ward, Lien Chieu dist., Da Nang, Vietnam

Trần Đức street, Hoa Khanh Nam ward, Lien Chieu dist., Da Nang, Vietnam